Use Case

Tank Inspection Workflow

Structured process to minimize production disruption and risk

Tank inspections are a critical service workflow to ensure safety, operational efficiency, compliance, and cost management. Used across various industries, these inspections monitor the integrity of tanks used for storage and transportation of potentially toxic or hazardous substances.

Inspections are routinely performed to prevent leaks, contamination, and tank failures that can lead to several types of risk – environmental, financial, and human safety. Sectors like oil and gas, utilities, pharmaceuticals, and agriculture rely heavily on tank inspection workflows to mitigate these risks and ensure continuity of operations.

CHALLENGE

Traditional inspection methods incur high costs, not to mention safety risks associated with having technicians work in confined spaces with little ventilation, amplifying the dangers of potentially hazardous substances. Additionally, thorough inspections introduce unavoidable disruptions to operations, and field leaders are forced to balance maintenance and safety against demanding production schedules and targets.

Due to these, critical tank inspections are sometimes performed less rigorously or forgone entirely, leaving companies vulnerable to catastrophic equipment failures. This dramatically causes unplanned, extended downtime and impacts production output even more than anticipated, with a cascading effect on potential safety and compliance risks.

SOLUTION

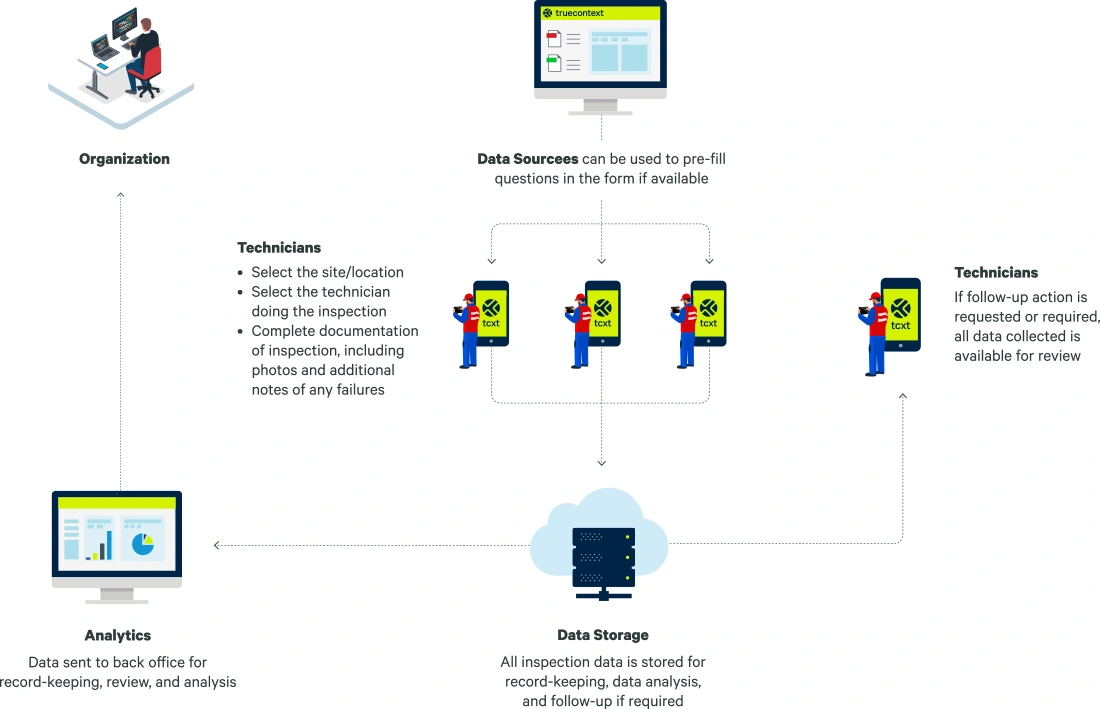

The TrueContext tank inspection workflow enables a well-planned and organized process to ensure that critical storage and transport containers are operating to optimal standards. It provides a single form that enables technicians to easily carry out inspections with the required individual steps, supported by resources that help identify problem areas depending on specific models. By using a single, streamlined form, the technician can select their location, go through each step of the inspection, and thoroughly document any issues they find.

The structured workflow allows technicians to work as efficiently as possible, with specific instructions on critical safety gear and practices that this unique environment calls for. The comprehensive data collected is date-stamped and integrated with your systems of record in real time so reports and analytics can be generated, which supports operations leaders in deciding the most optimal interval between tank inspections with the least production disruptions.

OUTCOMES

Enhanced technician safety

Your teams perform tank inspections as efficiently and quickly as possible, reducing their exposure to hazardous environments.

Reduced downtime and extended asset lifecycle

Routine tank inspections are optimally scheduled, minimizing catastrophic failures and extending lifespan of assets.

Improved productivity and efficiency

With built-in workflow guidance, your technicians perform better, more detailed inspections in less time.

Comprehensive compliance documentation

The streamlined app allows for thorough data collection, along with important metadata to create regulator-friendly reports.

Just-in-time maintenance

As tanks need to be out of service during inspections, creating a predictive schedule takes eliminates unnecessary visits while maintaining optimal operation.

Reduced costs associated with failures

Well-maintained assets go into catastrophic failure much less often, reducing risk of irrecoverable damage.

WORKFLOW FEATURES

Forms

- Data source (list of pre-defined job sites and locations, employees and contractors, and inspection checklists)

- Data destinations

Documents

- Full log of the status of every step of each inspection along with supporting photos and documentation for any issues discovered during each step of the inspection

- Technician signature

- Custom document layout is also available

Data & Analytics

- Extraction of list report data to Excel is also available

Minimize production disruptions with TrueContext

Book a 15-minute chat to learn how you can make TrueContext work for you.