Let’s look at some sobering facts about field service safety. The National Safety Council notes a worker suffers an on-the-job injury every seven seconds. Installation, repair, and maintenance work hold standing in the top five occupations with the largest number of workplace injuries.

While safety has always been a concern for field service leaders, the question remains whether there’s even more that they can do to help their employees stay out of harm’s way and get home to their families after a hard day’s work.

This article will explore how the nature of work has evolved over the years, what the future holds as innovative technology solutions take center stage as an effective way to ensure field worker safety.

What is Industry 4.0?

Just when we all get used to one industrial revolution, another one replaces it! The first industrial revolution was in the late 18th century with all the buzz around steam power and mechanization. Then came the second one in the mid-to-late 19th century with modernization powered by electricity and communication networks. Lucky number three, businesses moved from being focused on industrial methods with the digital revolution with the mainstream adoption of computers, automation, and impressive electronics in the workplace to help us do our jobs more effectively.

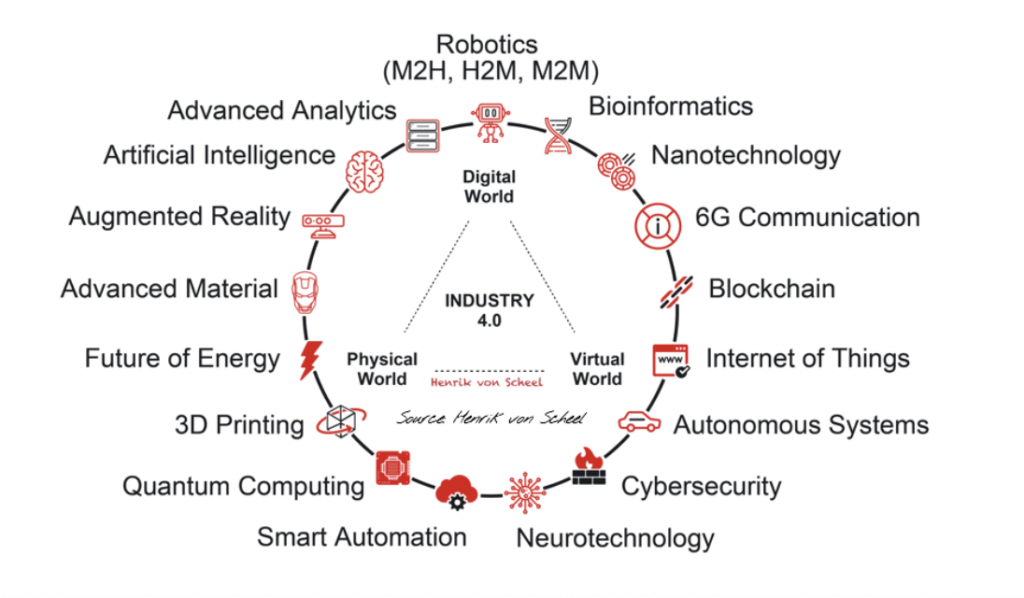

Impressive advancements in technology have birthed the fourth industrial revolution, also referred to as Industry 4.0. The father of this term, Henrik von Scheel, defines Industry 4.0 as “the fusion of the digital, virtual, and physical worlds, manifested as the “Cyber-Physical Systems” and “Metaverse” to name a few.” In the image below from von Scheel’s website, you’ll notice many familiar technologies integral to this new phase of rapid transformation.

What about safety management?

Industry 4.0 is expected to provide companies with the ability for computers, software, devices, and equipment to be integrated seamlessly to communicate information in real-time to increase efficiency and reduce human error. The manufacturing industry has started to reap the benefits of Industry 4.0, with many digital transformation efforts having already been adopted. However, much of the focus has been primarily on digitizing operations.

One area where transformation efforts absolutely need to be increased is safety management. Many organizations are reliant on manual processes such as paper-based systems and Excel spreadsheets. This dependency leaves companies in a reactive rather than preventative position when it comes to dangerous incidents. Preventing injury or death in the first place is the goal. It’s vital to engage in proper mitigation efforts to ensure field service technician safety. Companies will achieve this objective with predictive analytics.

Industry 4.0 and field service technician safety

Industry 4.0 is driven by the adoption of technologies that facilitate faster, more intelligent decision-making capabilities and new work methods for businesses. To augment the many benefits to be gained, consideration must be given for how organizations can also use emerging technology to impact field service workers’ health and safety positively.

Taking an Industry 4.0 view of workplace and job site safety is of primary importance. Companies are already investing in and leveraging many solutions to advance their operational goals, but these can also be used to protect and improve the lives of technicians. Digital equipment to advance field service worker safety includes:

- Drones

- Robots and exoskeletons

- Remote sensors

- Wearable devices including smart PPE and smart visors

- Augmented reality (AR)

Beyond their usefulness in helping technicians avoid dangerous situations, these solutions are powerful in their ability to collect valuable predictive data that can be used to prevent incidents and advance occupational health and safety (OHS) efforts.

Field service organizations can use all the data collected from the devices listed above to identify reasons for workplace injuries, such as overheated or exhausted field techs. With enough information gathered on technicians and their activities, companies can leverage AI to predict when future incidents may arise for a specific employee, asset, or environment.

Learning from the past to determine a model for the future is essential – and can easily be done through a monitoring dashboard. You certainly don’t get these kinds of results with a pen and paper or from pouring through documents in a filing cabinet.

Conversely, field technicians provided with context and intelligence from data from an organization’s back office and cloud systems are better equipped to stay safe.

Why data-driven safety matters for field service operations

Predictive analytics is vital for field service safety, yet according to the National Safety Council, only 12% of companies in high-risk industries like manufacturing, utilities, construction are using technologies that leverage these insights.

Companies that fail to use preventative analytics are at risk of facing several negative repercussions faced by organizations, including:

- Lawsuits

- Lengthy audits

- Downtime of machinery, assets, or job sites

- Loss of contracts should customers take their business elsewhere

- Negative perceptions that can impact hiring, investment, and future contracts

How ProntoForms helps advance field service safety

As organizations embrace Industry 4.0, there’s a greater need for ProntoForms. The abundance of data acquired through these emerging technologies must flow freely to and from the right locations to ensure safety for field service technicians. Our solution helps digital data move from mobile devices used in the field to office systems where it can become actionable across multiple teams and systems of record. It also helps bring valuable information into the hands of technicians who perform complex work and deserve to be supported with everything they need to complete a job.

With ProntoForms’ no-code field team platform, you can:

- Contextually embed safety procedures directly into work processes

- Deploy new compliance protocols a few clicks—to a team or entire workforce

Being proactive is the key to avoiding negative outcomes and enable field technicians to be efficient and perform their jobs as safely as possible. Book a demo to discover how we set you up to track, manage, and assess work including inspections and audits, installation and maintenance, and more.