Workplace health & safety standards save lives.

The Occupational Safety & Health Administration ensures safe and healthy working conditions for Americans by enforcing standards and providing workplace safety training. The agency says that since it was established in 1971, workplace fatalities have declined by 62 per cent, and occupational injury and illness rates have declined by 40 per cent. Worker deaths are down from about 38 every day in 1970 to 12 per day in 2014.

The agency has compiled a list of most frequently cited standards violations following worksite inspections by federal OSHA, including scaffolding requirements, chemical hazard communication, powered industrial trucks, and lockout/tagout procedures.

Mobile solutions have empowered organizations, from SMBs to large enterprises, to meet and exceed these stringent, life-saving standards.

Conduct thorough site and equipment inspections

Regular inspections are critical to mitigating incidents that can have devastating consequences. OSHA mandates routine inspections for an array of workplace equipment. Industrial trucks must be examined before being placed in service for the day, and cannot be placed in service if the examination shows any condition compromising safety. Scaffold components must be inspected by a qualified person for visible defects before each shift and after any occurrence which could affect a scaffold’s structural integrity.

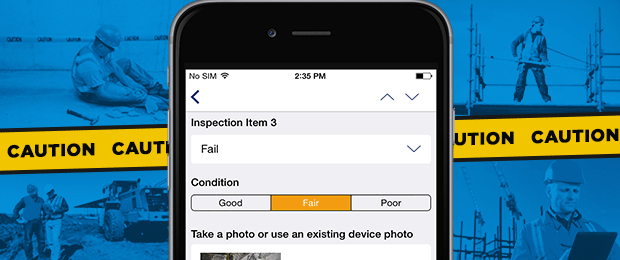

Environmental, health & safety personnel can make use of mobile safety forms to conduct thorough inspections by creating custom checklists and capturing site photos to highlight specific hazards. Mobile forms ensure that frequent inspections – even daily – are conducted by the right personnel, and that the data is captured accurately and shared with the right people in a timely fashion. Inspections can be automatically scheduled and dispatched to ensure ongoing maintenance is completed.

Build and set up equipment to proper specifications

OSHA mandates that certain workplace equipment has to be constructed to outlined specifications. Scaffolding, for example, has to be designed in such a way that it can support, without failure, its own weight and at least four times the maximum intended load. Scaffolds must be constructed by a qualified person and constructed and loaded in accordance with that design.

Workplace engineers can harness mobile checklists to ensure that this equipment is built to proper specifications and set up with all safety procedures followed.

Provide employees with in-depth training

Employee training and evaluation is essential to successfully navigating workplace hazards. Employees who drive powered industrial trucks have to go through training consisting of formal instruction, practical training, and evaluation in the workplace. Employees need to be provided with effective training on hazardous chemicals at the time of their initial assignment and whenever a new chemical hazard is introduced.

EHS professionals can create custom mobile checklists and evaluation forms and even embed instructional videos from YouTube directly into forms. To communicate the hazards of workplace chemicals, employers can mobilize safety data sheets so that they are available to all employees on their mobile devices.

Ensure lockout/tagout procedures are followed

Whenever any servicing or maintenance work is performed on a potentially dangerous piece of equipment, the machine has to be isolated from the energy source and rendered inoperative. A locking device must be fastened to the equipment or power source so that no energy can be supplied. A tag has to be fixed to the locking device to indicate that it should not be started again until the tag is removed.

Mobile forms prevent workers from overriding lockout/tagout procedures because the work order form for one of these machines can’t be accessed until the tags have been removed by a specified employee.

Workplace safety incidents are on the decline, while at the same time, the tools used to tackle compliance have been evolving rapidly. This article covers just a few of the various OSHA standards that mobile forms can tackle. Mobile forms empower organizations to achieve a wide breadth of OSHA standards, as well as service level agreements, industry regulations, and other business benchmarks.