Today, mobile automation in the mining industry is a popular topic among service leaders for several reasons, including:

- Enhanced working and safety conditions

- Increased output

- Management of mobile fleets and increased vehicle efficiency

- Operation of remote mines

- Production evaluation

- Optimization of performance and increased effectiveness

- Requirements for environmental, social, and governmental (ESG) compliance

We recently spoke with Sam and Geneviève, two training superintendents from the Iron Ore Company of Canada (IOC). Sam oversees mining operations and all mobile equipment on site. Geneviève handles rail, port, energy, and processing areas. They both manage a team that uses ProntoForms (now TrueContext) daily. They kindly shared their experience working with ProntoForms (now TrueContext) on a mining automation project with their learning management system (LMS), which addressed issues with manual processes and the resulting consequences on training and safety.

Can you summarize your mining operations in Labrador City and Sept-Îles?

We are a top producer and exporter of high-grade concentrate and premium iron ore pellets in North America, with an average iron grade of over 66%. In the province of Newfoundland and Labrador, we operate a mine with five active pits, a concentrator, and a pelletizing facility that are all close to Labrador City.

The “Labrador Trough,” where IOC is situated, is a well-known basin with sizeable deposits for the supply of high-grade iron ore products. We also own the Quebec North Shore and Labrador Railway (QNS&L), a 418-kilometer railway that connects our operations in Labrador with our port facilities in Sept-Îles. We can produce 23 million tonnes of iron ore annually.

With a team of over 2,900 employees, we provide value for our customers, employees, communities, and shareholders by delivering our high-quality concentrate and pellets across the globe.

How does a mining automation-focused training process impact your mine?

Our training documentation must be accurate to meet safety standards and government legislation, protect workers, and support internal and external audits.

How did this process work before?

Each day, we recorded all training entries manually. Trainers filled out paper forms and attendance sheets in the field, requiring time to enter the data into our learning management system.

First, this resulted in a lot of paper use, which posed a tremendous environmental challenge for us. It was also difficult to process information accurately and efficiently. There was an increased risk of error because our administrators had to enter data by hand in the field, which, unfortunately, often resulted in massive backlogs.

How did you try to resolve this?

When we first started using forms, we tried using a variety of applications, but there were still a lot of problems because of the gap between the forms and our LMS. As a result, we continued to produce a lot of paper and struggled with manual administrative entry – something that is a key target area for mobile automation in the mining industry.

We discovered ProntoForms (now TrueContext) while looking for a solution that could support this connection. Eventually, through a collaboration between our IOC Training team, our IS&T department, the LMS provider, and ProntoForms (now TrueContext), we developed automated training forms we could upload to our LMS. Since then, we’ve created a variety of forms to support our training requirements, including an attendance log for all of our general training.

What does your process look like today?

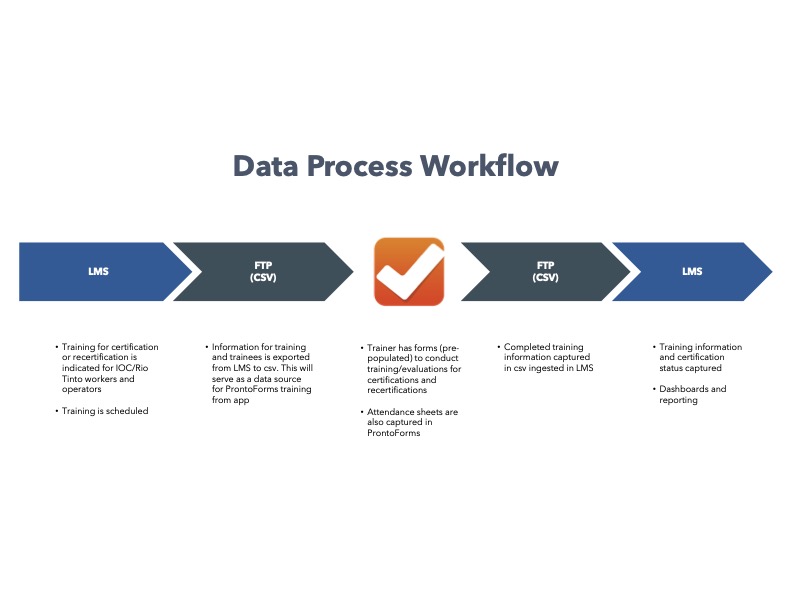

In order to ensure accurate daily forms, we push data from our LMS through an FTP site every evening to populate our forms. This data includes information about employees, a training catalog, and a list of trainers.

Then the trainers will use the forms on tablets to evaluate our employees in partnership with internal and external providers. As soon as they submit their forms, the data wirelessly uploads to the FTP server. The last step is to upload the training submissions back into our LMS each night.

How has mining automation helped your training process?

The benefits of mining automation have been many. Our administrators of the training management system, who had to enter every training activity, had a very demanding workload because of the large number of paper assessment forms that had to be completed.

Now that our LMS automatically synchronizes with our forms, our administrators no longer have to print out assessment forms in order to complete their field certifications. Because they always have one tablet with all the training evaluation forms at their disposal, they’re free to focus on providing fast and systematic evaluations.

This has helped us dramatically reduce their workload, increasing their effectiveness and job satisfaction. As an added benefit, it has helped us cut our usage of paper. In the end, it gives us confidence that the data in the system will always be timely and accurate when we need to provide reports for our management team.

What’s next for you in terms of mining automation?

Working with our vendor, we’d like to create training activities in our LMS and export them directly to ProntoForms (now TrueContext). That way, the trainers won’t need to enter training data in the field because our admins will set it up in directly in our LMS.

Conclusion

As you can see, mining automation has allowed IOC to achieve incredible results. Before, they recorded all training entries manually. Besides having a lot of paper and extra work, IOC had a very difficult time recording data accurately. Now, they have a system that is accurate and error-free, helps reduce paper use, and lessens overall workload so trainers can concentrate on their tasks. If you’re ready to transform your field team’s processes like IOC, let’s talk.