In the bustling, ever-developing world of field service, organizations find themselves at a crossroads between two distinct areas of focus–a technician-centric approach and an asset-centric one, both crucial aspects of field service.

Choosing Paths: Technician-Centric and Asset-Centric Approaches

A medical device manufacturer installs, maintains, and repairs critical equipment. Understanding the direct impact of equipment downtime on patient care, they focus on skill development and empowerment. They invest in additional training programs for their engineers, ensuring they are both technically proficient and aware of current regulatory and compliance requirements.

Conversely, an HVAC company serving large commercial establishments adopts an asset-centric approach. The implications of equipment failures, especially during peak seasons, drive them to focus on asset longevity and performance. They use industrial IoT devices and AI algorithms to minimize asset downtime while maximizing productivity and lifespan.

The Integration Conundrum: Merging Two Worlds

Integrating multiple tools to manage diverging priorities becomes common when businesses operate in these field service domains. The workforce is also becoming more diverse, complicating the field service equation. Despite these factors, minimizing the divergence of these two realities remains essential for field service leaders everywhere.

The Disconnect: Navigating Through Implications

A skilled engineer from the medical device manufacturer answers a call to a city hospital’s radiology department. While calibrating an MRI machine, she faces a problem. She can’t access the machine’s service history or recent diagnostic data. This causes her to resort to conduct tests that she wouldn’t have to do if there had been available asset data. This inefficiency forces her into time-consuming, redundant checks or calls to colleagues and the head office.

The hospital staff, who are already busy enough as it is, get visibly frustrated as patients waiting for their MRI scans become more restless. The consequence for field service organization? Reduced productivity due to lower first-time fix rates and unnecessarily longer periods to complete routine repairs.

Miles away, a technician on a remote offshore platform tries to resolve a critical issue with drilling equipment. As he examines the malfunctioning blowout preventer system, a vital safety device, he realizes he cannot access its service history or recent diagnostic data due to inadequate system integration. This lack of information forces him to perform manual checks and call the head office, all while the clock is ticking.

The facility manager, aware that every minute of downtime equates to significant revenue loss, grows increasingly anxious. This prolonged downtime strains the relationship between the technician and the facility manager and risks tarnishing the company’s reputation – all the while creating a ballooning opportunity cost. In the oil & gas industry, the average revenue loss due to unplanned downtime is estimated at $500,000 per hour. In both scenarios, the ripple effects are evident. Gaps like these can cost money, drive technicians away, and lead to gaps in data visibility.

Intelligent Apps: Building your field service tech stack for your needs

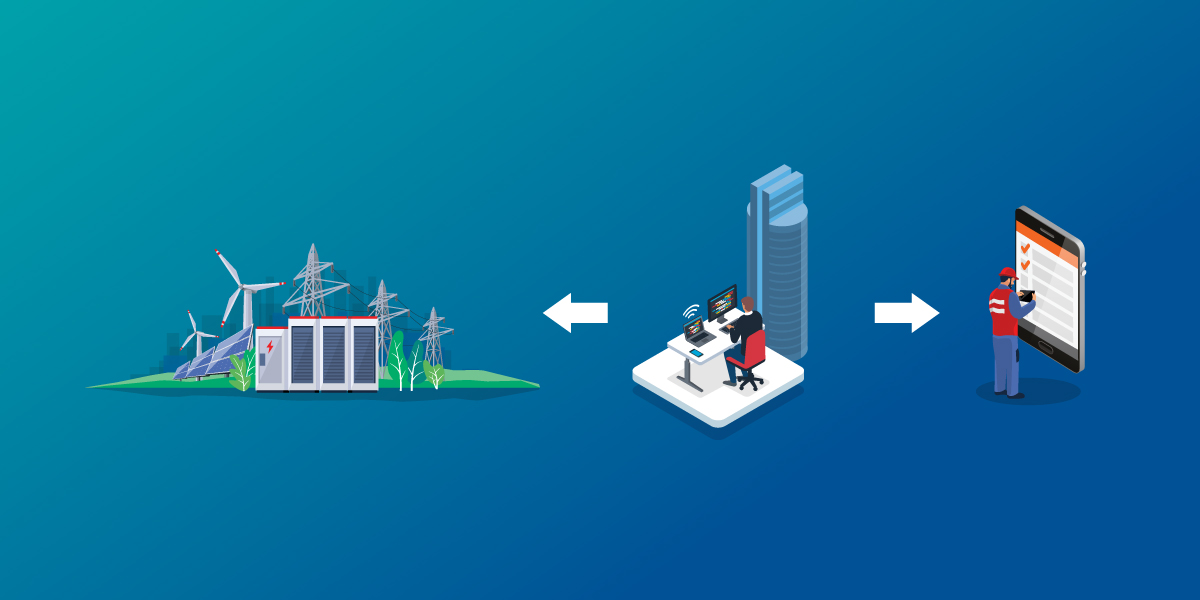

Whether an organization currently focuses on assets or technicians, intelligent apps offer more than just data management and efficiency. They ensure that each piece of the field service puzzle connects effectively, delivering the right information to the right person at the right time.

One of the most pressing issues in field service today is administrative overhead. As highlighted at Field Service Hilton Head, many technicians find themselves bogged down with paperwork and data gathering. While many mobile forms apps address this pain point, intelligent apps seamlessly bring data together into an ecosystem that allows for greater possibilities. This streamlined approach enables technicians to confidently focus on their primary responsibilities, improving job satisfaction in an industry where expertise is progressively dwindling.

For leaders, the feedback that intelligent apps provide is also important. Real-time data logging and predictive analytics naturally become a lot more accessible. This data-driven approach facilitates continuous improvement, allowing leaders to pinpoint process and asset inefficiencies, reduce attrition, and ensure optimal performance in every step of the workflow.

Navigating Through the Complexities of Field Service

In the dynamic landscape of field service, balance is critical. Although each approach has its strengths, what determines success is how an organization unifies people, technology, and processes. Intelligent apps are the bridge between assets and technicians, helping to foster an environment where technicians thrive. As service demand continues to increase, a cohesive approach to process automation and intelligent apps is now essential for any organization looking to remain agile and competitive.