Use Case

Leak Detection and Repair (LDAR) Workflow

Ensure human and asset safety and reduce regulatory risk

Leak detection and repair (LDAR) is a common yet critical use case across many industries – and having a streamlined, mobile method to perform this process opens up opportunities for service organizations to improve asset uptime and mitigate worker and regulatory risk.

LDAR is essential for oil & gas across all production streams, especially in meeting compliance mandates to control fugitive emissions of volatile organic compounds (VOCs) and methane. In medical equipment, pharmaceuticals benefit from LDAR workflows to detect and prevent harmful substances from contaminating the drug manufacturing process. Similarly, utility companies rely on this use case to identify leaks in water treatment, while mining and mineral processing leverage it to monitor toxic gases like hydrogen sulfide and ammonia.

CHALLENGE

Organizations using paper-based leak detection methods run the risk of errors associated with manual data collection. Paper is prone to damage, loss, and legibility challenges, which introduces the very real possibility of data loss and integrity issues. Additionally, a non-digital method reduces a service operation’s ability to leverage real-time, free-flowing data between the field and the back office, not to mention the massive and unnecessary resource drain of personnel to digitize and process data collected from the field.

This cascades into bigger issues down the road, including less and slower insight generation, making it difficult for companies to effectively analyze data, create reports, and identify trends. Lack of visibility can mean the difference between continuous uptime and unplanned downtime, as well as achieving compliance and massive regulatory fines. Field teams are also subjected to preventable risk as they work in environments where toxic leaks might go undetected. Finally, in drug manufacturing, contaminants may enter the production stream unnoticed and cause significant harm to health outcomes for customers, not to mention millions of dollars in resulting fines.

SOLUTION

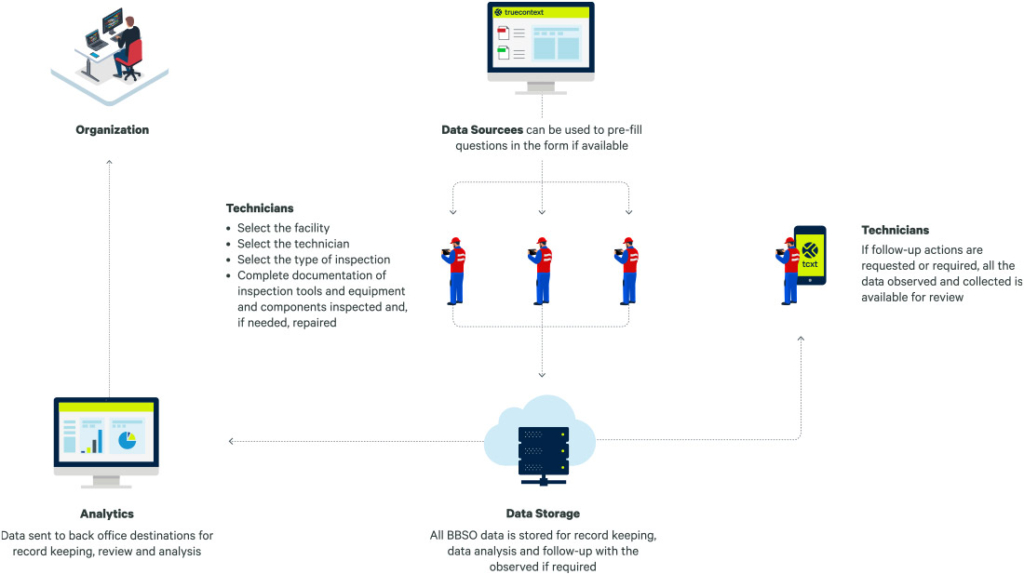

TrueContext has designed a digital LDAR inspection workflow with key integrations into critical systems of record, such as EAM and FSM platforms, to help organizations rapidly transform how they detect and repair leaks in their installed asset base. Utilizing a data integrity-centric UX, the workflow enables your field teams to collect accurate and reliable information on your assets, efficiently identify leaks based on specific indicators, and dispatch and conduct necessary work to mitigate downtime. The guidance built into the workflow helps your technicians take remedial action as quickly and efficiently as possible without overlooking critical data.

The out-of-the-box integrations feed seamless into your back-office systems, allowing your operation and business leaders to perform more comprehensive data analysis and plan future maintenance proactively. The workflow design allows for audit-friendly reporting as well, incorporating time stamps and geolocation data that is stored directly into your connected platforms without the need for re-entry or processing by staff. The platform’s analytics capability provides easy-to-use reports and dashboards to distill your operational visibility into actionable plans, such as refining maintenance schedules and iterating workflows for better fit in your operations.

OUTCOMES

Improved uptime

Gathering continuous data on your LDAR work to build proactive maintenance models that mitigate costly downtime.

Elevated multi-stakeholder safety

Ensure the safety your workers, customers, and assets by detecting and repairing leaks in your production.

Increased productivity and efficiency

Streamline the process by eliminating paperwork and delivering guided workflows to your teams in the field.

Reduced regulatory risk

Prevent the risk of massive regulatory fines stemming from undetected toxic leaks that harm the environment, your workers, and consumers.

WORKFLOW FEATURES

Forms

- Data source (list of pre-defined facilities, inspectors, inspection methods, inspection tools, the equipment and components found at these facilities)

- Data destinations

Documents

- Full log of every detected leak along with supporting photos and documentation

- Full log of all equipment and components on which a repair was made or attempted along with supporting photos and documentation

- Full log of all equipment and components that could not be inspected along with supporting photos and documentation

- Technician signature

- Custom document layout is also available

Data & Analytics

- Extraction of list report data to Excel is also available

Digitize your LDAR with TrueContext

Book a 15-minute chat to learn how you can make TrueContext work for you.